Services

MES Solutions Services

MES Solution Brief

From electronics to medical equipment, from automobiles to heavy equipment, every industry is facing increasingly fierce market competition. Cheap prices can no longer be used as the only magic weapon for competition. Customers expect that manufacturing companies can provide higher product quality, faster production speed, and better delivery flexibility. Increasing labor costs and rising raw material prices have increased pressure on costs. Various laws and regulations that are increasingly stringent in foreign countries have imposed higher requirements on product exports. The continuous shortening of product life cycles has brought material management challenges, and products have been launched quickly. It is often accompanied by a large quality risk. With the rapid development of these enterprises, these problems at the manufacturing site are becoming more and more prominent. The traditional manual management and ERP software are inadequate in this regard. Manufacturing companies must find new ways to manage the breakthrough.

As a manufacturing execution system, MES helps companies solve the above problems well by opening the "black box" at the manufacturing site. MES (Manufacturing Execution System) tracks and feedbacks the production progress, quality control, and material consumption of each product under the work order in a timely manner, and focuses on production efficiency, straight-through rate, downtime and waiting according to the set early warning indicators. Warning, realizing full transparency, complete traceability, real-time error prevention and pre-management at the manufacturing site.

Rockwell FactoryTalk ProductionCentre MES Solution

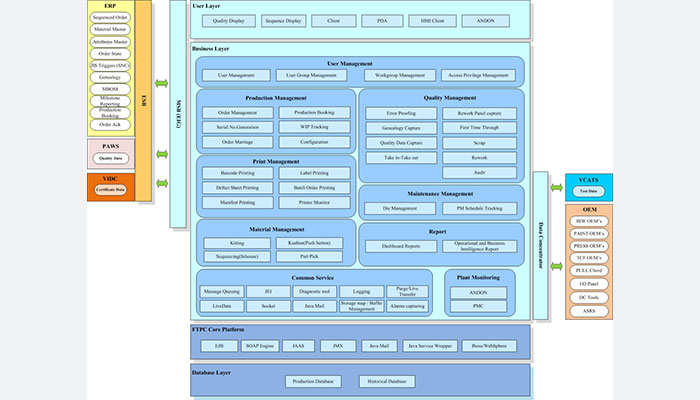

Rockwell's automated MES platform-FactoryTalk ProductionCentre, aims to enable suppliers' material information, pre-process and assembly line material consumption and production information, and finished product flow information to be collected in real time, accurately and completely through data barcode collection throughout the production process. Traceability

Transparency in all aspects of material purchase, storage, delivery, assembly, finished product storage, out of storage, branch out of storage and end users.

MES-Product Overview

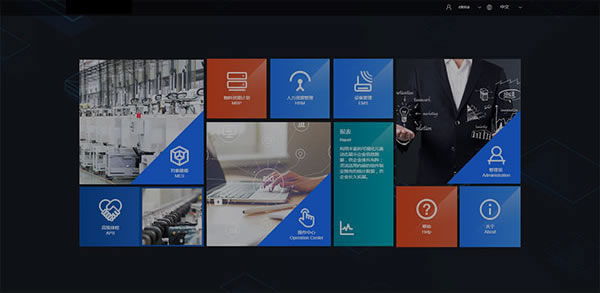

Based on the MES platform, combined with many years of consulting and implementation experience and consultant elites, jointly develop MES, including systems: MES, APS, HRM, MRP, WMS and EMS, from enterprise resource planning-efficiency capacity, from resources-production products-products After-sale, the overall intelligent manufacturing construction of manufacturing enterprises that implements unified planning and management of resources, equipment, products, and production capacity to achieve resource integration, production supervision and traceability, KPI performance evaluation, and equipment prevention and early warning.

Platform advantage

Based on web B / S architecture design, one-click upgrade system version, easy to use and easy to operate.

Suzhou Huaguan Technology JapserMes platform supports multi-language and more international models.

Drag-and-drop process route design, visual modeling scenarios, from concrete to abstract, from tedious to simple.

Application design based on cloud architecture, adopting private cloud + public cloud deployment, combining tradition and modernity, giving wisdom in production.

Platformized products support extended attributes for modeling objects, such as materials, to meet the development needs of different industries.

Support for report extension. Users can independently develop reports through the reporting tool and seamlessly integrate with the platform.

Expansion of configuration-driven functions to avoid a lot of secondary development work.

The modules are independent and can be implemented gradually according to actual requirements to meet the flexible business requirements of SMEs.

Using the Java programming language, the backup power is strong, and it faces a wide range of people; at the same time, it provides a wealth of secondary development documents, which is easy for secondary development and maintenance.

The native reports are rich, from design to production kanban, forward tracking, reverse tracing, etc., to enable users to carefully control the production process.

MES-platform module planning

MES

- Accurately trace and monitor the production process

- Collect complete production information

- Custom production process

- Guarantee product quality standards

- Cooperate with lean workshop production

- Statistical analysis of report data

APS

- Flexible configuration of scheduling strategies

- Fully automated production scheduling

- Schedule Constraint Dynamic Association

- Full Gantt chart visualization

- Allow temporary deployment plans

MRP

- Manage product structure in all aspects

- Show inventory file status in real time

- Production and inventory

- Control plans and reports

- Precision calculation

- Process and operation

WMS

- Warehouse automation and refined management

- Flexible job engine settings

- Direct and standardize warehouse operations

- Intelligent warehouse management

- Reduce warehouse material storage

- Visual monitoring of warehouse resources

HRM

- Build a complete group organization structure

- Comprehensive maintenance of employees' comprehensive information

- Reasonable statistics of employee hours and compensation

- Talent input and output management

- Accurate KPI performance evaluation of employees

EMS

- Early warning and prevention equipment

- Timely abnormal online alarm

- Real-time equipment data collection

- Equipment TPM comprehensive management

Tell free:800-262-9895

Tell free:800-262-9895 info@amaxgs.com

info@amaxgs.com