Technologies

Factory Automation

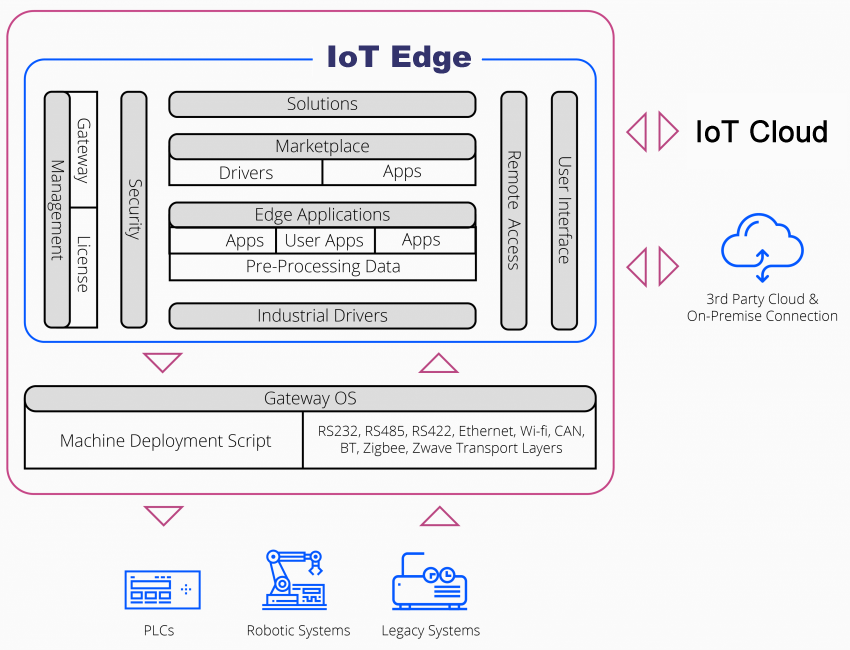

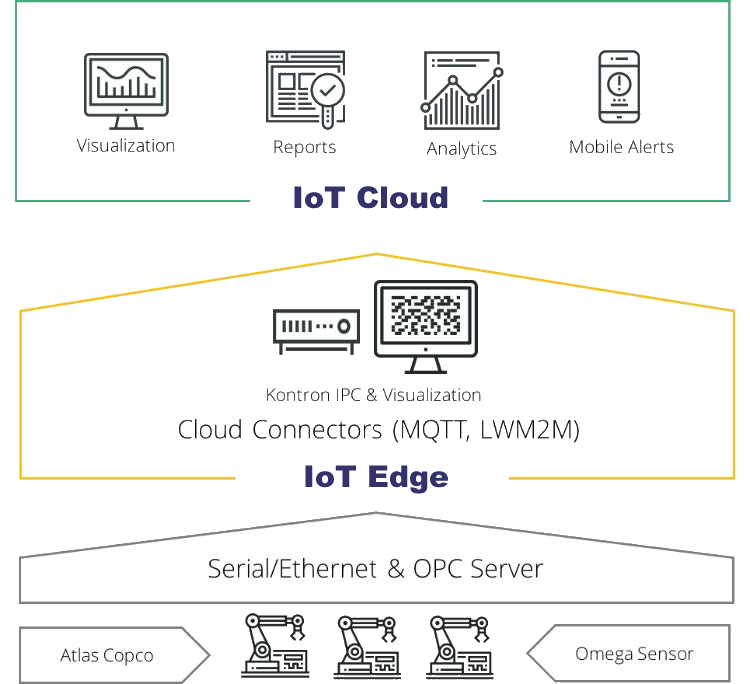

The AGS IoT platform and AGS Edge gateway software solution provide valuable business insight in the Industrial Manufacturing and Connected Car markets. The following readymade solutions demonstrate how AGS and AGS Edge work best.

Industrial Manufacturing

AGS's Industrial Manufacturing IoT solutions manage the communications and processing of data from embedded legacy equipment on the factory floor.

IoT solutions

- Machine Health

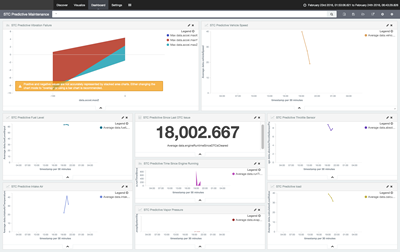

Production line anomalies from old machine systems can require long-term and costly maintenance. IoT Cloud and IoT Edge enable predictive maintenance as a precautionary solution, eliminating the instantaneous cost of failure on old machine systems.

Save Time

- Reduce and eliminate the instantaneous cost of failure using IoT Cloud and IoT Edge.

Increase Efficiency

- Save time and money in the production process and optimize maintenance schedules on older machines.

- OEM Predictive Maintenance

AGS’s edge and cloud-based solution, IoT Edge, can collect, standardize, isolate, secure and push device data to the IoT platform, enabling predictive maintenance of potential failing systems in the short and long term.

Generate Business

- Create new revenue streams and business models as a result of understanding asset data.

Understand Your Business

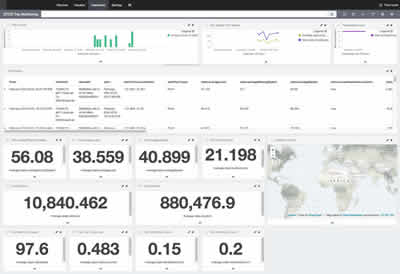

- Collect better analytics for assets being sold, leading to value-added services for consumers and users such as visualizations and real-time machine health monitoring.

Increase Customer Loyalty

-Provide value to the end customer by decreasing failure costs, while also increasing brand awareness and customer loyalty.

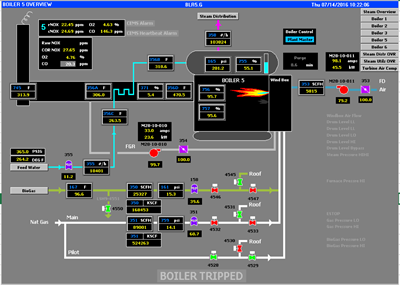

- Real-time Production Monitoring

AGS provides a combined solution for both operational technology (OT) and information technology (IT) by leveraging the IoT Cloud and IoT Edge platforms.

Save Time & Money

- Decrease the cost associated with assembling and disassembling products with a robotic production system.

Improve Quality

- Provide better quality control over final assembled items, through real-time monitoring.

Increase Customer Loyalty

Customers receive quality assurance, allowing them to provide better SLAs around their final products.

- Asset & Material Tracking

The IoT Edge and IoT Cloud Connected Industry Software Platform facilitates an integrated asset management system that ensures logistics optimization through easy location and monitoring of assets and material.

Save Time

- Quickly locate critical equipment and reduce inventory time to deliver more timely information for decision making.

Increase Productivity

- Measure real-time physical inventory of assets and enhance productivity by remotely monitoring assets and infrastructure.

Security

- Improve security by preventing assets from leaving the premises and keeping designated assets out of unauthorized areas.

Quality

- Improve quality and quality control by maintaining full traceability of the digital thread from raw material to product.

Visibility

- Enhance visibility by tracking critical assets in real-time using RFID, shop floor sensors and warehouse management systems.

- Connected Operations Intelligence

The IoT Cloud and IoT Edge Connected Industry Software Platform enables Connected Operators intelligence including internal and external operating conditions, systems, and events as well as the traditional disciplines of quality, inventory, maintenance, and quality.

Visibility

- Achieve insight into asset and energy availability, reliability, and benchmarking. Reduce downtime, improve utilization, reduce maintenance, know repair and operations (MRO) inventory, improve design.

Efficiency

- Reduce energy costs, improve production efficiency, improve asset performance, improve design and commissioning.

Performance

- Enable traceability and serialization and reduce the scope and impact of adverse events. Improve inventory and manufacturing performance.

Flexibility

- Enable flexible manufacturing through reduced lot size, increased customer responsiveness, increased asset utilization, and increased production capacity.

Tell free:800-262-9895

Tell free:800-262-9895 info@amaxgs.com

info@amaxgs.com